Ordering a 2026 Corvette is less about choosing a car and more about configuring a performance system. Unlike typical vehicles where trim alone defines character, the Corvette’s behavior is determined by how trims, powertrains, suspension packages, and aerodynamic options interact.

For performance-focused buyers, understanding how these elements stack together is essential to building a Corvette that aligns with real driving intent rather than surface-level specifications.

Corvette Trim Structure Explained

The Corvette lineup is organized around core trims that establish drivetrain layout and baseline capability. Each trim then supports multiple performance paths through package selection.

Primary Corvette trims include:

Read the rest of this entry »The Corvette Z06 and the Z07 package are often discussed as if they represent two different cars. In reality, the Z07 is a comprehensive performance amplification layer built on top of the Z06’s mid-engine platform. Understanding the difference requires moving past horsepower figures and into aerodynamics, thermal management, braking endurance, and chassis behavior under sustained load.

For 2026, the decision between Z06 and Z06 equipped with Z07 is fundamentally a decision about how far toward dedicated track performance the driver intends to go.

Core Z06 Foundation

The Z06 begins with a purpose-built performance platform centered around a naturally aspirated flat-plane-crank V8 mounted in a mid-engine configuration. This engine’s high-revving character places significant thermal and airflow demands on the vehicle, which the Z06 addresses through extensive cooling architecture.

Base Z06 characteristics include:

Read the rest of this entry »The move to a mid-engine layout was the single most consequential engineering decision in Corvette history. For 2026, every Corvette variant benefits from a chassis architecture that fundamentally reshapes how the car accelerates, turns, brakes, and communicates at the limit. This is not a styling evolution or a packaging exercise. It is a structural solution to the physical constraints that defined front-engine Corvettes for decades.

By relocating the engine behind the driver and ahead of the rear axle, Chevrolet changed how mass is distributed, how weight transfers under load, and how the tires are asked to do their work. The result is a Corvette that behaves like a true modern supercar, not just in peak numbers, but in repeatable, controllable performance.

Mid-Engine Corvette Models

Every modern Corvette built on the C8 platform uses a mid-engine layout. This architecture places the engine behind the driver and ahead of the rear axle, forming the foundation for all current and future high-performance Corvette variants.

The following Corvette models are mid-engine:

Read the rest of this entry »2025 Corvette Owner Guide: Break-In Procedure, Driving Modes & First-Month Performance Tips

Taking delivery of a 2025 Corvette is more than a milestone purchase. It is the start of a mechanical relationship that rewards disciplined early ownership. While modern Corvettes are engineered with advanced materials, tight tolerances, and extensive factory testing, the first month of driving still plays a critical role in how the vehicle performs long term. Break-in is not about limiting capability. It is about conditioning systems so they deliver consistent, repeatable performance when fully unleashed.

This guide explains how to approach break-in, how to use driving modes effectively, and what habits matter most during the first month of ownership.

Why Break-In Still Matters on a Modern Corvette

Even with precision machining and modern assembly processes, internal components require controlled wear to establish ideal contact surfaces. Break-in allows these parts to mate correctly under varied loads and temperatures.

Key systems affected during break-in include:

- Piston rings seating against cylinder walls for proper sealing

- Bearings establishing stable oil film behavior

- Valvetrain components synchronizing under load

- Transmission clutches and gears bedding in smoothly

Rushing this process can lead to uneven wear that affects responsiveness and durability over time.

Break-In Mileage and Driving Approach

Rather than focusing on a single mileage number, break-in should be approached as a phase defined by driving behavior. Varying engine speed and load is more beneficial than gentle driving alone.

Best practices during early ownership include:

- Avoiding sustained engine speeds at a constant rpm

- Varying throttle input throughout drives

- Refraining from full-throttle acceleration early on

- Allowing the engine to reach operating temperature before increasing load

This approach promotes even wear and stable performance characteristics.

RPM Management During Early Miles

High engine speed generates increased friction and heat before components are fully conditioned. Early driving should keep engine speed within moderate ranges while still allowing variation.

RPM-related guidance includes:

- Avoiding extended operation near redline

- Letting the engine experience both low and mid-range rpm

- Using smooth acceleration rather than abrupt throttle inputs

- Avoiding aggressive downshifts that spike rpm early

Gradual exposure prepares the engine for high-performance operation later.

Transmission Break-In and Shift Behavior

The Corvette transmission is engineered for performance, but it also benefits from early conditioning. Clutch packs and gear interfaces require controlled engagement to develop smooth operation.

Transmission-focused habits include:

- Smooth throttle application during shifts

- Avoiding repeated launch-style starts

- Allowing the transmission to warm fully before spirited driving

- Letting shift logic adapt naturally over time

These habits support consistent shift quality and long-term reliability.

The Importance of Thermal Cycling

Thermal cycling refers to allowing components to heat up fully and then cool down repeatedly. This process stabilizes materials and relieves internal stress.

Effective thermal cycling includes:

- Driving long enough to reach full operating temperature

- Allowing the vehicle to cool between drives

- Avoiding exclusively short trips during early ownership

- Mixing city and highway driving

Balanced thermal cycles contribute to long-term mechanical stability.

Understanding Corvette Driving Modes

The 2025 Corvette offers multiple driving modes that adjust throttle response, steering effort, suspension behavior, and drivetrain calibration.

Core driving modes include:

- Tour mode for smooth, compliant daily driving

- Sport mode for sharper response and engagement

- Track mode for maximum performance calibration

- Custom or Z Mode for personalized settings

Each mode changes how aggressively the vehicle responds to driver inputs.

Driving Mode Strategy During Break-In

During the break-in phase, conservative use of aggressive modes helps manage load while still allowing varied driving conditions.

Recommended early mode use includes:

- Favoring Tour or Sport for daily driving

- Using Track mode sparingly early on

- Avoiding repeated launch control use

- Gradually increasing performance exposure as mileage accumulates

This strategy balances enjoyment with mechanical care.

Corvette Z Mode Explained for New Owners

Z Mode allows drivers to configure individual performance parameters such as throttle response, suspension stiffness, and steering feel.

Early ownership considerations for Z Mode include:

- Selecting moderate throttle response initially

- Avoiding maximum transmission aggressiveness early

- Gradually increasing settings as the vehicle completes break-in

Z Mode offers flexibility without forcing an all-or-nothing performance profile.

First-Month Driving Habits That Influence Long-Term Performance

Small habits during the first month have a lasting impact on how the Corvette feels and responds.

Positive early habits include:

- Smooth throttle transitions

- Progressive braking rather than abrupt stops

- Controlled steering inputs

- Paying attention to vehicle feedback

These behaviors promote balanced wear across systems.

When Track Driving Should Begin

Track driving places sustained, extreme demands on the engine, transmission, brakes, and cooling systems. It should be postponed until break-in is complete and systems are fully conditioned.

Indicators that the Corvette is track-ready include:

- Completion of initial break-in mileage

- Stable fluid temperatures under spirited driving

- Consistent throttle and shift response

- Confidence in braking performance

Waiting ensures performance remains consistent lap after lap.

Early Maintenance Awareness

While major service may not occur in the first month, owners should remain attentive to vehicle condition.

Early ownership checks include:

- Monitoring fluid levels

- Observing warning indicators or messages

- Listening for abnormal noises

- Noting changes in drivability or shift behavior

Addressing concerns early supports long-term reliability.

What New Corvette Owners Should Evaluate

During the first month, owners should evaluate:

- Engine responsiveness as mileage increases

- Transmission smoothness and consistency

- Brake feel under varied conditions

- Ride quality and chassis balance

This awareness helps owners understand how the vehicle evolves through break-in.

Final Perspective on First-Month Corvette Ownership

The 2025 Corvette is engineered for extreme performance, but that capability is best realized through thoughtful early ownership. Break-in is not about restraint. It is about preparation. By managing load, using driving modes strategically, and building smooth habits, owners ensure the Corvette delivers its full potential when it matters most.

A properly conditioned Corvette rewards its owner with confidence, consistency, and durability that extend from daily driving to track-level performance.

C8 Dual-Clutch Transmission Engineering: Why the DCT Improves Corvette Acceleration & Track Consistency

The shift to a dual-clutch transmission in the mid-engine Corvette C8 marked one of the most consequential engineering decisions in the model’s history. This change was not made for convenience or novelty. It was required to fully unlock the performance potential of the C8 platform by delivering faster acceleration, tighter power delivery control, and repeatable performance under track conditions.

Understanding how the C8 dual-clutch transmission works explains why the Corvette accelerates harder, shifts faster, and behaves more consistently than previous generations.

Why Corvette Moved to a Dual-Clutch Transmission

The C8’s mid-engine layout fundamentally changed drivetrain packaging and performance priorities. Traditional torque-converter automatics and manual transmissions could not deliver the precision or packaging efficiency required.

Key reasons for adopting a DCT include:

- Ability to package efficiently behind a mid-mounted engine

- Faster shift times than manual or traditional automatic designs

- Continuous torque delivery during gear changes

- Improved thermal management under track loads

The transmission became an active performance component rather than a passive intermediary.

How a Dual-Clutch Transmission Works

A dual-clutch transmission uses two separate clutches to manage alternating gear sets. One clutch controls the odd-numbered gears, while the other controls the even-numbered gears.

Operational fundamentals include:

- Pre-selection of the next gear before the shift occurs

- One clutch disengages as the other engages

- Power delivery remains uninterrupted during shifts

- Gear changes occur in milliseconds

This architecture eliminates the pause in acceleration common with single-clutch systems.

Acceleration Gains Through Continuous Power Delivery

Acceleration is not just about horsepower. It is about how consistently that power reaches the wheels. The C8 DCT improves acceleration by maintaining engine load through shifts.

Acceleration benefits include:

- No torque interruption between gears

- Faster 0 to 60 times through uninterrupted thrust

- More efficient use of engine powerband

- Reduced drivetrain shock during hard launches

This allows the Corvette to stay in its optimal performance range throughout acceleration.

Shift Speed and Driver Control

Shift speed is critical in both straight-line acceleration and corner exit. The C8 DCT delivers shifts faster than human-operated manuals and most automatics.

Shift characteristics include:

- Immediate upshifts under full throttle

- Crisp downshifts under braking

- Rev-matched gear changes without driver input

- Consistent behavior regardless of driver fatigue

For track driving, this consistency allows drivers to focus on line and braking rather than gear timing.

Track Consistency and Heat Management

Track driving places extreme thermal stress on transmissions. The C8 DCT is engineered to handle repeated high-load shifts without degradation.

Engineering considerations include:

- Dedicated cooling circuits for transmission components

- Lubrication systems designed for sustained high rpm

- Materials selected to withstand heat cycling

- Calibration that prevents overheating without reducing performance

These features support consistent lap times rather than a single peak run.

Integration With the Mid-Engine Layout

The DCT integrates tightly with the C8’s mid-engine architecture. Its placement contributes to balanced weight distribution and improved vehicle dynamics.

Layout benefits include:

- Compact transmission design reduces mass behind the rear axle

- Improved weight balance for handling

- Shorter drivetrain path reduces power loss

- Enhanced traction during acceleration

Transmission design directly supports chassis performance rather than compromising it.

Dual-Clutch Versus Traditional Automatics

Compared to torque-converter automatics, a DCT offers sharper response and greater efficiency under load.

Key differences include:

- No torque converter slip during acceleration

- Faster gear engagement

- More direct mechanical connection

- Reduced heat generation under performance driving

This makes the DCT better suited for sustained high-performance use.

Reliability and Durability Considerations

High-performance transmissions often raise reliability concerns. The C8 DCT addresses this through robust engineering and conservative operational limits.

Reliability-focused features include:

- Extensive durability testing under track conditions

- Reinforced clutch packs

- Software controls that manage stress without dulling response

- Redundant cooling and lubrication strategies

These measures allow the DCT to deliver performance without sacrificing longevity.

Daily Driving Versus Track Use

Despite its track capability, the C8 DCT remains manageable in everyday driving. Calibration allows smooth low-speed operation when performance is not demanded.

Street driving benefits include:

- Smooth gear changes during light throttle use

- Predictable behavior in traffic

- Immediate response when acceleration is needed

- No learning curve for drivers unfamiliar with manuals

This dual personality broadens the Corvette’s usability.

What Enthusiasts Should Evaluate

When evaluating the C8 DCT, enthusiasts should consider:

- Preference for seamless acceleration versus manual involvement

- Importance of track consistency

- Desire for repeatable performance under load

- Long-term durability expectations

The DCT is engineered for drivers who value precision and consistency.

Final Perspective on the C8 Dual-Clutch Transmission

The dual-clutch transmission is central to the Corvette C8’s performance identity. By eliminating power interruption, improving shift speed, and maintaining consistency under extreme conditions, the DCT allows the Corvette to exploit its mid-engine platform fully.

This is not a convenience feature. It is a performance tool that enables faster acceleration, more predictable handling, and repeatable track results. For drivers who understand that true performance comes from precision as much as power, the C8 dual-clutch transmission is a defining element of the modern Corvette.

2025 Corvette Owner Guide: Break-In Procedure, Driving Modes & First-Month Performance Tips

The first month of Corvette ownership sets the foundation for how the car performs over its entire life. Modern Corvettes are built with tight tolerances and advanced materials, but mechanical components still benefit from a structured break-in period. This process is not about limiting enjoyment. It is about conditioning critical systems so they deliver consistent performance, durability, and responsiveness long term.

Understanding how to manage break-in, driving modes, and early driving habits helps owners protect their investment while preparing the Corvette for future performance use.

Why Break-In Still Matters on a Modern Corvette

Even with advanced manufacturing, internal engine and drivetrain components require controlled wear to mate surfaces properly. Break-in allows parts to establish optimal contact patterns under varying loads and temperatures.

Key systems affected during break-in include:

- Piston rings seating against cylinder walls

- Bearings establishing proper oil film behavior

- Valvetrain components synchronizing under load

- Transmission clutches and gears bedding in

Skipping or rushing this process can lead to uneven wear that impacts performance consistency.

Corvette Break-In Mileage and Load Management

The early miles are less about a fixed distance and more about how the vehicle is driven. Varying engine speed and load allows components to experience different pressures and temperatures.

Best practices during early driving include:

- Avoiding sustained high rpm operation

- Varying speed rather than using cruise control constantly

- Applying moderate throttle rather than full acceleration

- Allowing the engine to fully warm before higher loads

Gradual exposure to load helps components settle correctly.

RPM Guidance During Break-In

High engine speed places increased stress on internal components before surfaces are fully conditioned. Early operation should stay within moderate rpm ranges while still allowing the engine to experience varied use.

RPM-related considerations include:

- Avoiding extended high rpm driving

- Using the full rev range gradually over time

- Allowing engine speed to rise and fall naturally

- Avoiding aggressive downshifts early on

This controlled approach supports proper ring seating and bearing conditioning.

Transmission Break-In and Drivetrain Behavior

The Corvette’s transmission also benefits from an initial break-in period. Clutch packs and gear surfaces require controlled engagement to develop smooth operation.

Transmission-focused tips include:

- Smooth throttle inputs during shifts

- Avoiding repeated launch-style starts

- Allowing the transmission to reach operating temperature

- Letting shift behavior normalize gradually

These habits improve long-term shift quality and durability.

Thermal Cycling and Its Importance

Thermal cycling refers to allowing components to heat up and cool down repeatedly. This process stabilizes materials and reduces internal stress.

Effective thermal cycling includes:

- Driving the vehicle for moderate distances

- Allowing full warm-up before spirited driving

- Letting the vehicle cool after driving sessions

- Avoiding short trips exclusively during early ownership

Balanced use supports long-term reliability.

Understanding Corvette Driving Modes

Modern Corvettes offer multiple driving modes designed to tailor throttle response, steering, suspension, and drivetrain behavior.

Common driving mode functions include:

- Tour mode prioritizing comfort and smooth response

- Sport mode sharpening throttle and steering feel

- Track mode optimizing performance systems

- Custom modes allowing driver-defined preferences

Each mode influences how aggressively the vehicle responds.

Driving Mode Use During Break-In

During the initial ownership period, conservative modes help manage load while still allowing varied driving conditions.

Recommended early mode usage includes:

- Favoring Tour or Sport for daily driving

- Using Track mode sparingly early on

- Avoiding aggressive launch control use

- Gradually introducing performance modes over time

This approach balances enjoyment with mechanical care.

Corvette Z Mode Explained

Z Mode allows drivers to configure performance settings independently, blending comfort and aggression based on preference.

Z Mode considerations during early ownership include:

- Using moderate throttle and suspension settings initially

- Avoiding maximum engine and transmission aggressiveness

- Gradually increasing performance parameters as mileage accumulates

This customization allows drivers to ease into full performance capability.

First-Month Driving Habits That Matter

Early ownership habits shape how the Corvette feels long term. Small choices accumulate into meaningful differences.

Positive first-month habits include:

- Smooth throttle transitions

- Progressive braking rather than abrupt stops

- Steering inputs that remain controlled

- Paying attention to vehicle feedback

These behaviors support balanced component wear.

When Track Driving Should Begin

Track driving places the highest demands on the engine, transmission, brakes, and tires. It should be delayed until break-in is complete and systems are fully conditioned.

Track readiness indicators include:

- Completion of initial break-in mileage

- Normalized engine and transmission behavior

- Stable fluid temperatures under load

- Confidence in braking and handling response

Waiting ensures the vehicle performs consistently under extreme conditions.

Early Maintenance Awareness

Although major maintenance may not occur in the first month, owners should remain attentive to vehicle condition.

Early ownership checks include:

- Monitoring fluid levels

- Observing any warning messages

- Listening for abnormal noises

- Noting changes in shift behavior

Addressing concerns early supports long-term reliability.

What New Owners Should Evaluate

During the first month, owners should evaluate:

- Throttle responsiveness as mileage increases

- Shift smoothness and consistency

- Brake feel under varying loads

- Ride comfort and handling balance

This feedback helps owners understand how the vehicle evolves through break-in.

Final Perspective on First-Month Corvette Ownership

The Corvette is engineered for extreme performance, but that capability is best unlocked through disciplined early ownership. Break-in is not about restriction. It is about preparation. By managing load, using driving modes thoughtfully, and developing smooth habits, owners set the stage for years of confident performance.

A properly conditioned Corvette rewards its owner with consistency, responsiveness, and durability that can be enjoyed on the street and the track alike.

2025 Corvette Z06 vs. Z07 Aero Engineering: Downforce, Cooling & High-Speed Stability Explained

Aerodynamics is not about appearance on the Corvette Z06. It is about mechanical grip, thermal control, and stability at speeds where tires and suspension alone are no longer enough. The difference between the standard Z06 aerodynamic configuration and the Z07 performance package lies in how aggressively Chevrolet engineers use airflow to keep the car planted, cool, and predictable under sustained track loads.

Understanding the aero engineering behind the Z06 and Z07 explains why these components materially change lap consistency, braking confidence, and driver feedback rather than simply adding visual drama.

Aerodynamics as a Grip Multiplier

At high speeds, aerodynamic downforce effectively increases tire load without adding vehicle weight. This allows the tires to generate more grip in corners, under braking, and during acceleration.

Key benefits of functional downforce include:

- Increased cornering speed without relying solely on mechanical grip

- Greater braking stability from higher vertical tire load

- Improved steering precision at speed

- Reduced reliance on traction control intervention

The Z06 aero system is designed to generate meaningful downforce while maintaining balance between the front and rear of the car.

Standard Z06 Aerodynamic Configuration

The standard Z06 features an integrated aerodynamic package engineered for high performance street driving with track capability. Every component is shaped to manage airflow intentionally rather than cosmetically.

Core Z06 aero elements include:

- Front splitter designed to reduce front-end lift

- Carefully contoured underbody airflow management

- Rear spoiler tuned for balanced rear stability

- Air extraction vents that reduce pressure buildup

This configuration delivers measurable downforce while remaining livable for regular road use.

Z07 Aero Package Overview

The Z07 package transforms the Z06 into a more track-focused machine by increasing aerodynamic load and cooling capacity. It is not a collection of isolated parts but a coordinated system.

Z07 aero upgrades include:

- Larger carbon-fiber front splitter

- Extended dive planes for front-end grip

- Tall rear wing designed for significant rear downforce

- Additional airflow management elements for cooling

These components work together to substantially increase total downforce at speed.

Downforce and High-Speed Stability

As speed increases, aerodynamic forces grow exponentially. The Z07 package is engineered to remain stable and predictable under these conditions.

High-speed stability benefits include:

- Reduced front-end lift during braking

- Improved rear stability during corner exit

- Greater confidence during high-speed direction changes

- Enhanced steering feel through consistent tire loading

This stability allows drivers to commit earlier and harder without unsettling the chassis.

Cooling as a Critical Aero Function

Aerodynamics on the Z06 and Z07 is as much about cooling as it is about grip. Track driving generates extreme heat across the engine, transmission, brakes, and tires.

Aero-assisted cooling strategies include:

- Directed airflow through heat exchangers

- Pressure reduction in wheel wells to improve brake cooling

- Venting hot air from high-pressure zones

- Maintaining airflow efficiency without excessive drag

The Z07 package further enhances cooling capacity to support repeated high-load laps.

Fixed Aero Versus Active Systems

The Corvette Z06 and Z07 rely on fixed aerodynamic components rather than active systems. This choice prioritizes predictability and reliability.

Advantages of fixed aero include:

- Consistent downforce regardless of system state

- Immediate response without actuator delay

- Reduced complexity and failure points

- Clear aerodynamic behavior at all speeds

For track use, consistency is often more valuable than adaptability.

Tradeoffs Between Z06 and Z07 Aerodynamics

While the Z07 package delivers superior track performance, it introduces tradeoffs that drivers should understand.

Considerations include:

- Increased drag at highway speeds

- More aggressive ride height sensitivity

- Reduced ground clearance in certain conditions

- Greater visual prominence of aero components

For drivers primarily using the car on public roads, the standard Z06 aero may offer a better balance.

Aero Balance and Driver Confidence

Aerodynamic balance refers to how evenly downforce is distributed between the front and rear axles. An imbalanced setup can make a car unpredictable.

Chevrolet engineers tuned Z06 and Z07 aero to:

- Maintain neutral handling at speed

- Prevent sudden oversteer or understeer

- Support stable braking zones

- Deliver consistent feedback through the steering wheel

This balance is essential for extracting performance safely.

Impact on Lap Times and Consistency

Downforce does more than reduce lap times. It improves consistency by allowing the car to behave the same way lap after lap.

Performance benefits include:

- Reduced tire overheating

- More predictable braking points

- Higher cornering repeatability

- Less reliance on electronic aids

For track drivers, consistency often matters more than a single fast lap.

Choosing Between Z06 and Z07 Aero Setups

Drivers should evaluate their intended use honestly when choosing between configurations.

The standard Z06 aero suits drivers who:

- Enjoy spirited street driving with occasional track use

- Want aerodynamic benefits without extreme tradeoffs

- Value everyday usability

The Z07 package suits drivers who:

- Plan frequent track sessions

- Want maximum grip and cooling

- Prioritize lap consistency over street comfort

Both setups are engineered for purpose rather than compromise.

Final Perspective on Corvette Z06 and Z07 Aerodynamics

The aerodynamic engineering behind the 2025 Corvette Z06 and Z07 demonstrates how airflow can be used as a functional performance tool. Rather than relying solely on power or suspension, Chevrolet leverages downforce and cooling to enhance grip, stability, and durability at speed.

For drivers who understand that true performance comes from balance and control, the difference between Z06 and Z07 aero is not cosmetic. It is structural, measurable, and central to how the car performs when pushed to its limits.

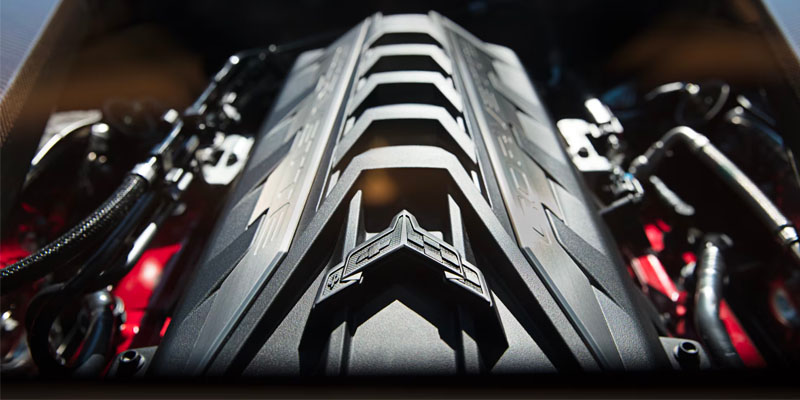

2025 Corvette Z06 LT6 Engine Deep-Dive: How the Flat-Plane Crank V8 Shapes Track Performance

The 2025 Corvette Z06 represents one of the most significant powertrain departures in Corvette history. At the center of that shift is the LT6 engine, a naturally aspirated 5.5-liter V8 engineered with a flat-plane crankshaft and designed from the outset for sustained track use. This engine does not borrow lightly from racing concepts. It applies them directly, prioritizing response, consistency, and durability at extreme engine speeds.

Understanding how the LT6 works explains why the Z06 behaves differently from traditional American V8 performance cars and why its performance feels precise rather than overwhelming.

What Makes the LT6 Engine Different

The LT6 is a clean-sheet engine developed specifically for the Z06. Unlike pushrod V8s used in previous Corvettes, the LT6 adopts a dual overhead camshaft layout with four valves per cylinder. This architecture supports airflow and valve control at very high engine speeds.

Key design characteristics include:

- Flat-plane crankshaft instead of a traditional cross-plane design

- Dual overhead camshafts for precise valve timing

- Lightweight rotating assembly to reduce inertia

- Valvetrain engineered for sustained high rpm operation

These elements work together to produce an engine that thrives near its redline rather than relying on low-end torque alone.

Flat-Plane Crankshaft Fundamentals

A flat-plane crankshaft arranges crank pins 180 degrees apart, similar to many racing and exotic engines. This differs from a cross-plane crankshaft, which spaces crank pins at 90 degrees.

Flat-plane crank advantages include:

- Even exhaust pulse spacing that improves scavenging

- Faster revving due to reduced rotating mass

- Sharper throttle response

- Improved breathing at high engine speeds

The tradeoff is increased vibration, which Chevrolet engineers addressed through careful balancing, engine mounting, and structural reinforcement.

Why the Z06 Sounds Different

The distinctive sound of the Z06 is a direct result of the flat-plane crankshaft and firing order. Evenly spaced exhaust pulses produce a higher-pitched, more exotic tone compared to the deep rumble of a cross-plane V8.

This sound is not a tuning choice. It is a byproduct of:

- Crankshaft geometry

- Exhaust pulse timing

- High engine speed operation

- Reduced overlap between firing events

The auditory character reinforces the engine’s racing lineage rather than traditional muscle car identity.

High-Revving Design and Throttle Response

The LT6 is engineered to operate at extremely high rpm, with a redline well beyond what most production V8s achieve. High engine speed capability allows the engine to produce power through airflow rather than displacement alone.

Benefits of high-revving design include:

- Linear power delivery as rpm increases

- Immediate throttle response

- Greater control when modulating power on track

- Reduced reliance on forced induction

For drivers, this translates to precision. Power builds predictably rather than arriving in a sudden surge.

Valvetrain and Internal Component Engineering

Sustaining high rpm requires more than strong pistons and rods. The LT6 uses a valvetrain engineered to maintain control under extreme conditions.

Engineering considerations include:

- Lightweight titanium intake valves

- Finger follower valvetrain design

- Precise camshaft profiles

- Robust timing chain system

These components ensure valve control remains accurate even during extended track sessions.

Lubrication and Cooling for Track Durability

Track driving places continuous load on an engine’s lubrication and cooling systems. The LT6 addresses this through advanced oil and thermal management.

Key systems include:

- Dry-sump lubrication to prevent oil starvation

- Multiple scavenging pumps for consistent oil flow

- Dedicated cooling circuits for critical components

- Optimized airflow through the engine bay

These systems allow the LT6 to maintain performance lap after lap rather than pulling power to protect itself.

Power Delivery and Track Consistency

The LT6’s naturally aspirated design delivers power in a predictable, linear manner. This consistency is critical for track driving where repeatable behavior builds driver confidence.

Track-focused advantages include:

- Immediate response to throttle inputs

- Consistent power output across sessions

- Reduced heat soak compared to turbocharged engines

- Enhanced control when exiting corners

Drivers can push the engine without guessing how it will respond.

Reliability Considerations for a High-Revving Engine

High-revving engines often raise concerns about longevity. The LT6 addresses this through materials selection, testing, and conservative operational limits relative to its design capability.

Reliability-focused engineering includes:

- Extensive endurance testing

- Reinforced block and rotating assembly

- Conservative oil and temperature thresholds

- Precision manufacturing tolerances

This allows the engine to deliver extreme performance while maintaining durability expectations.

Real-World Driving Versus Track Use

While the LT6 is track-focused, it remains usable on the street. The engine’s smooth power delivery and responsiveness make it manageable in daily driving situations.

Street driving benefits include:

- Smooth throttle modulation

- Predictable power delivery at low speeds

- Reduced reliance on boost for performance

- Mechanical connection between driver input and engine response

The engine rewards precision rather than brute force.

What Enthusiasts Should Evaluate

When evaluating the LT6, enthusiasts should consider:

- Preference for high-revving naturally aspirated power

- Track consistency over peak torque

- Throttle response versus forced induction acceleration

- Long-term durability under performance driving

The LT6 is designed for drivers who value control and repeatability.

Final Perspective on the LT6 Engine

The 2025 Corvette Z06 LT6 engine represents a philosophical shift for American performance. By embracing flat-plane crank architecture, high-revving operation, and race-derived engineering, Chevrolet created an engine that prioritizes precision, consistency, and driver confidence.

Rather than chasing peak numbers alone, the LT6 delivers performance that can be accessed repeatedly and reliably. For drivers who understand what makes an engine truly track-capable, the LT6 stands as one of the most technically significant V8s ever produced for a production Corvette.

A Corvette is a very special vehicle designed by some of America’s finest automotive engineers. It’s unwise to let an average mechanic work on your high-performance sports car. With specialist dealership service at your local Corvette dealership, you’ll keep your Corvette running smoothly for longer.

Read the rest of this entry »3 Key Services to Extend the Life of Your Corvette

Your Corvette is a fine vehicle, and you want to enjoy driving it for many years to come. As your Corvette dealership, we want to tell you about some of the long-term care services we offer that extend your vehicle’s life.